5/14/2025How Can Digitalization Be Effectively Advanced in the Process Industry?

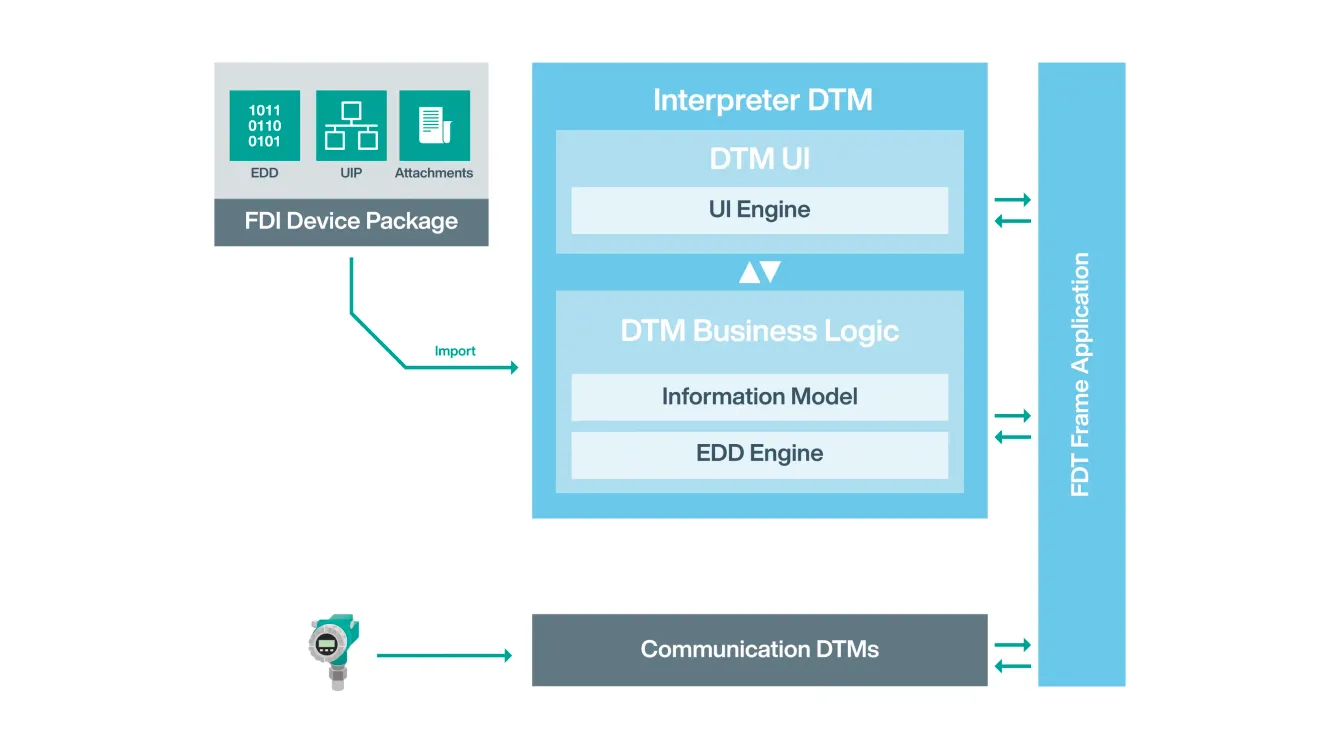

Standardized Information Models

At the core of any IIoT strategy lies a clearly defined information model that maps real-world objects along with their properties and relationships. This model serves as a bridge between the technical know-how of plant operators and the data-driven approach of IT. FDT and FDI provide the necessary level of detail—enhanced by PA-DIM (Process Automation Device Information Model), which defines a consistent parameter structure for all field devices.

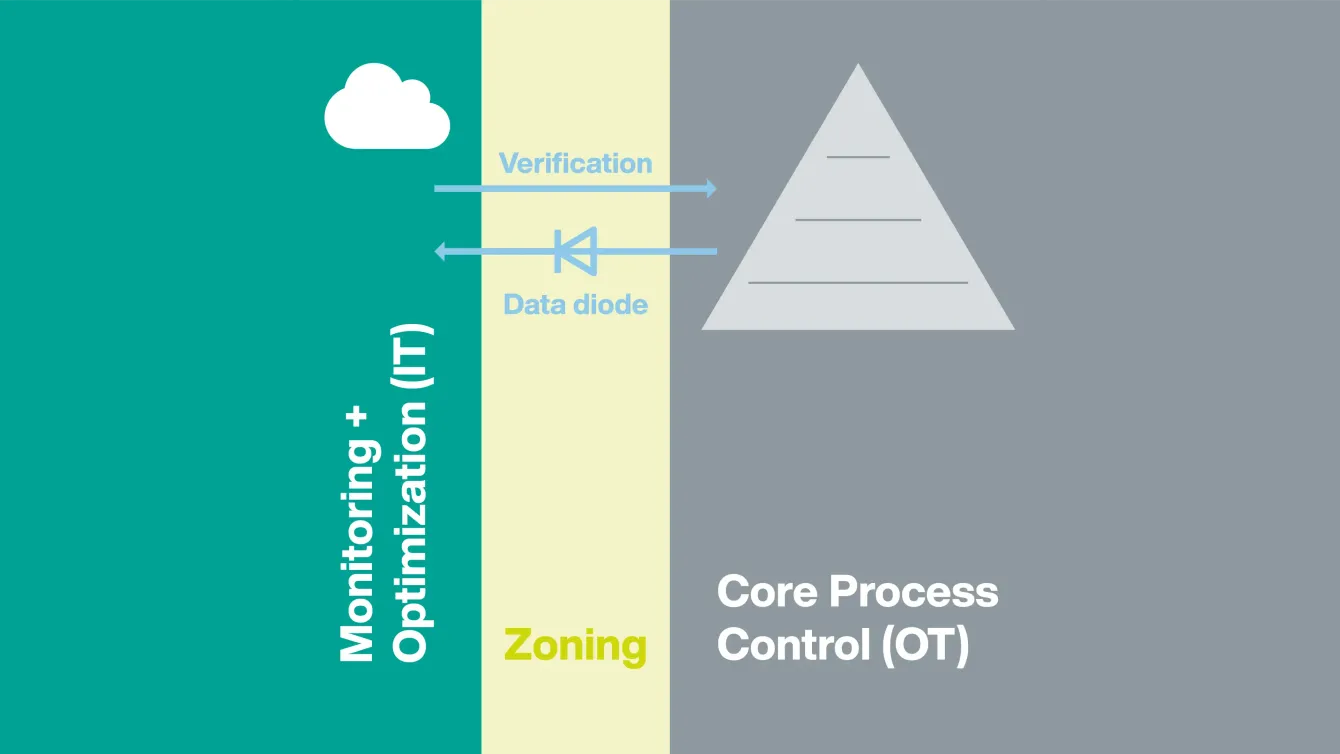

NOA: New Paths with Existing Infrastructure

With the “NAMUR Open Architecture” (NOA), the user association NAMUR has developed a concept that enables new digital services without modifying the proven process control systems. Through PA-DIM, field device information becomes accessible without interfering with the core process – ideal for optimization and predictive maintenance.

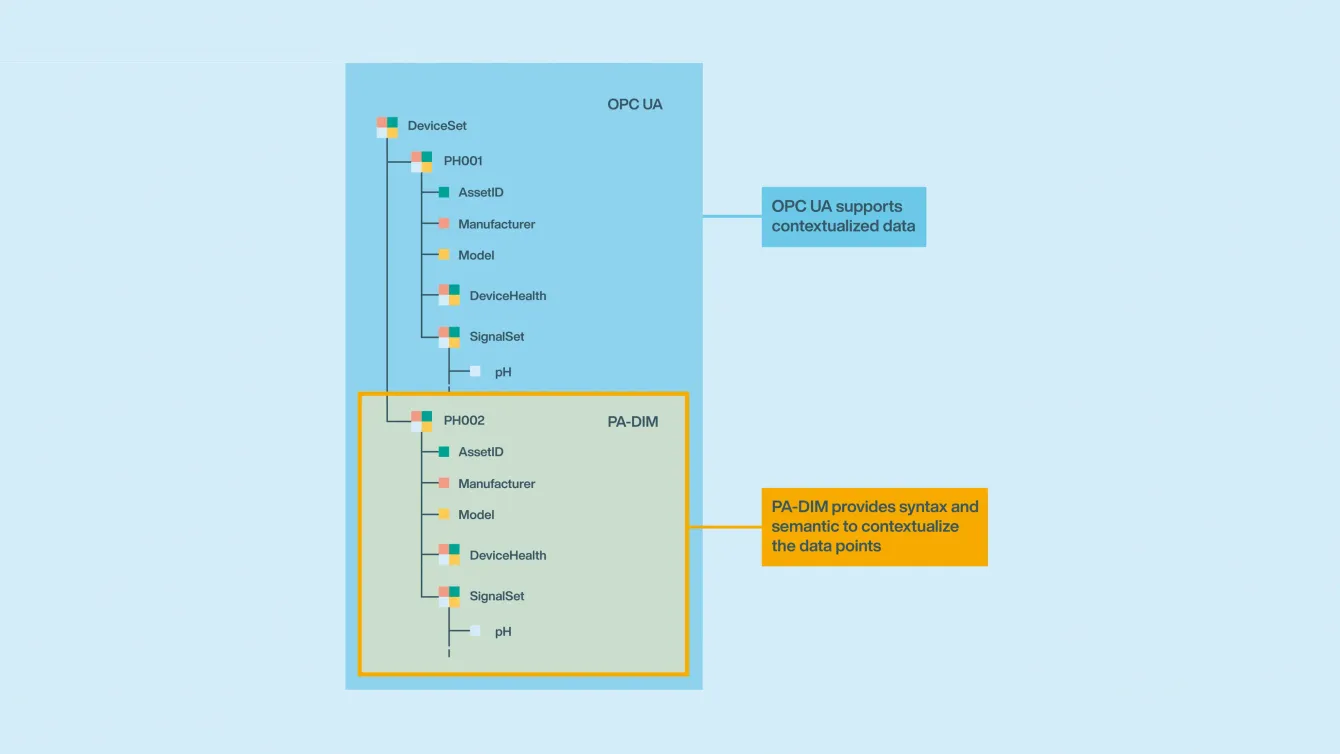

OPC UA: The Data Courier for IIoT

OPC UA has firmly established itself as a powerful standard for semantic data exchange in a machine-readable format that IT systems can interpret and process. This architecture enables not only secure transport, but also the structured and machine-readable description of information. As a result, PA-DIM models can be transmitted seamlessly to IT systems and cloud services.

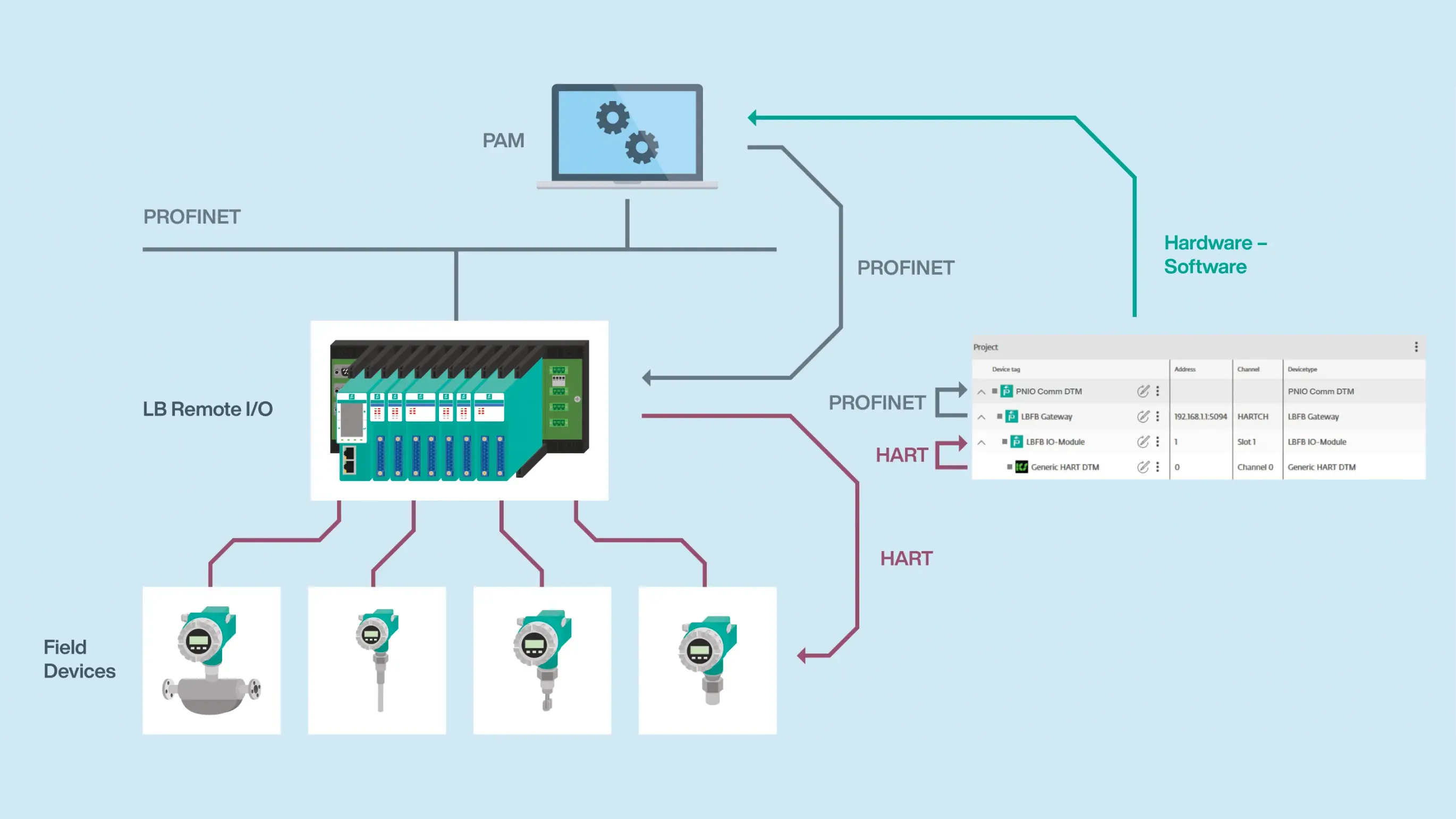

Hardware – The Backbone of Digitalization

Even though much is now software-based, the connection to the physical world remains essential. The Ethernet-APL Field Switch and proven Remote I/O components from Pepperl+Fuchs act as communication bridges between field devices and the overarching IT infrastructure.

Conclusion: Structured Digitalization for Effective IIoT

Digital transformation in the process industry doesn’t succeed through disruptive innovations, but through the smart interaction of established technologies. FDT, FDI, PA-DIM, OPC UA, and NOA provide the building blocks to implement IIoT applications in a meaningful and scalable way—preparing existing process plants for the challenges of tomorrow.