Object Detection and Process Analysis in Industrial Paint Curing Ovens

High-Temperature Sensors with IO-Link for Measurement and Monitoring

The Application

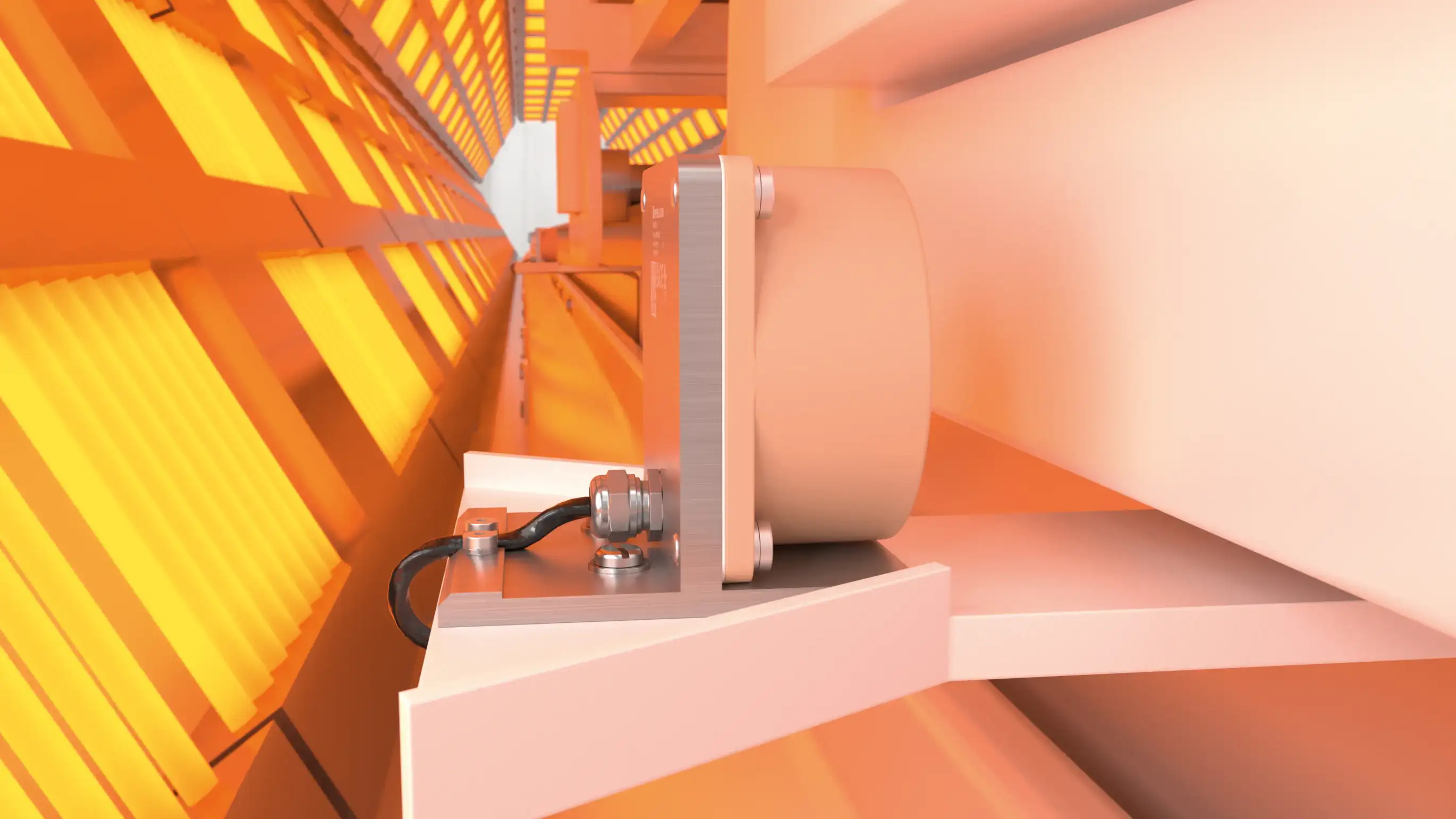

The drying systems of painting lines in the automotive industry place high demands on the materials and technology of the equipment. Temperature alternations of up to 250 °C, dust, harsh chemicals, and paint create extreme conditions. The freshly painted bodies are transported into the system on metal skids. Their correct positioning is essential for a smooth process.

The Goal

The presence of the skids should be reliably detected despite the extreme conditions. This requires solidly built sensors that function properly even at very high temperatures. The devices should be easy to install and simple to use. Since the system is usually loaded with several bodies and a correspondingly large number of skids per cycle, it must be possible to use several sensors in close proximity to one another.

The Solution

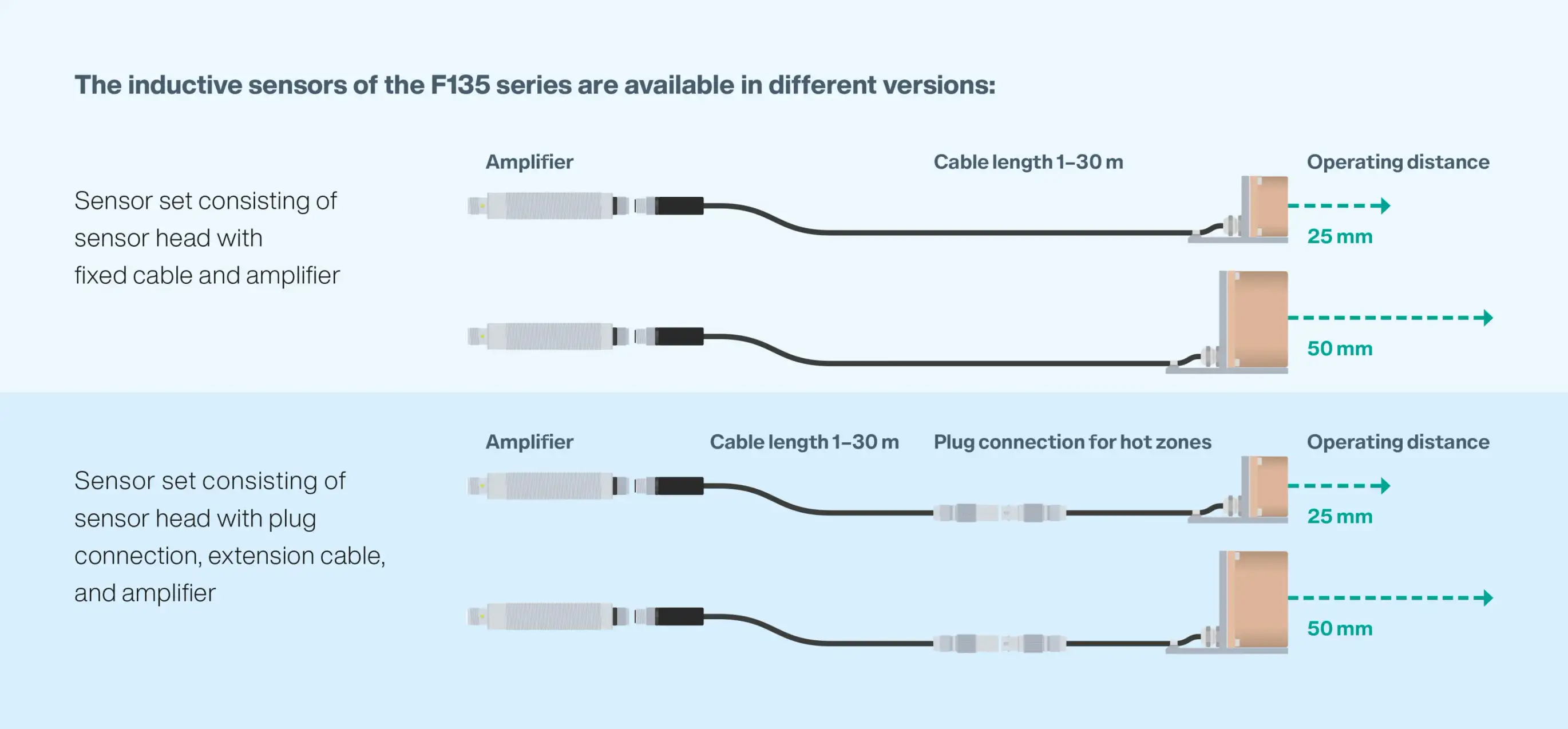

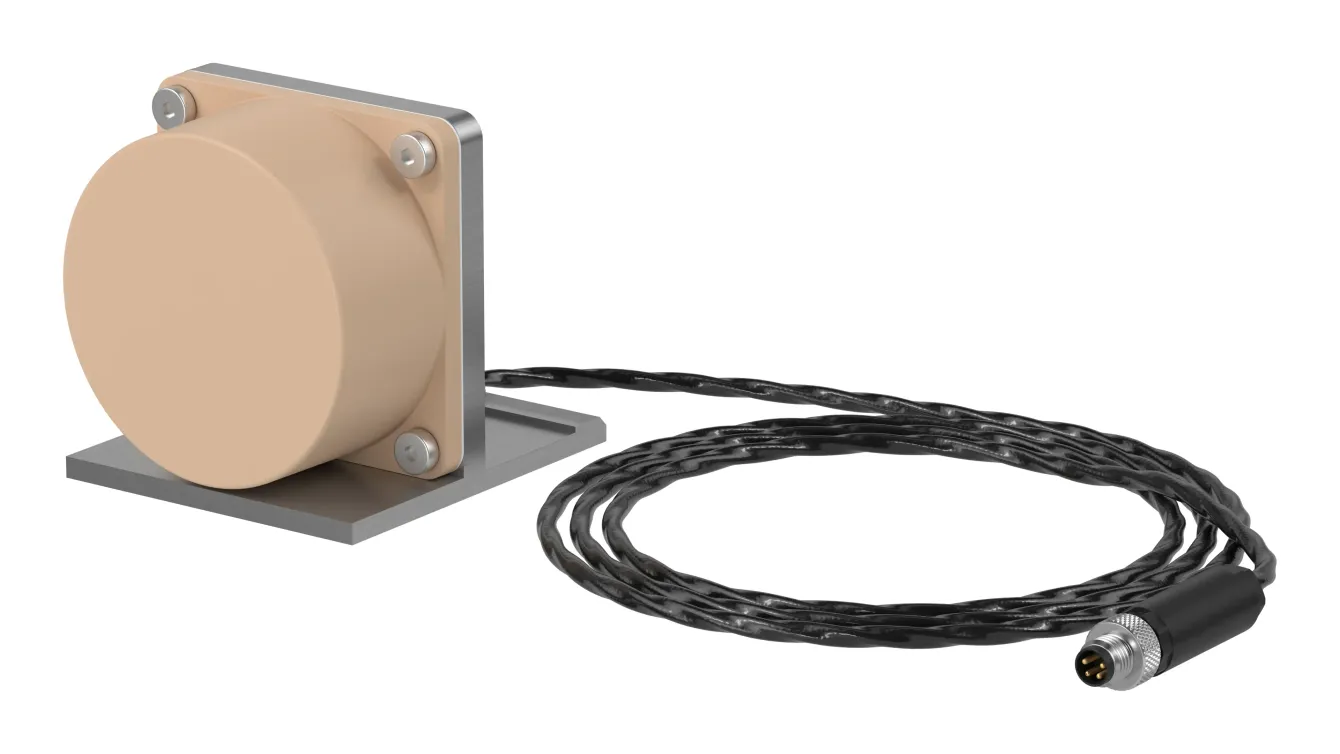

The F135 series inductive sensors are designed for high-temperature applications. They ensure reliable object detection and offer additional installation flexibility with their large operating distance of up to 50 mm. Even when the sensor heads are mounted directly next to each other, the automatic synchronization of the devices ensures trouble-free operation. The devices achieve an especially long service life; their minimal temperature drift ensures consistently reliable detection.

The plug-and-play principle streamlines both commissioning and sensor head replacement in the event of maintenance. Replacing the sensor head does not require re-parameterizing the amplifier or adjusting the operating distance via a potentiometer. Instead, the integrated IO-Link interface enables efficient parameterization. In addition to transmitting process data, it also provides limit value warnings and diagnostic information regarding the sensor head’s status.

Technical Features

- Stable object detection up to 50 mm

- Powerful noncontact measurement principle

- Minimal temperature drift even at very high temperatures

- Plug-and-play replacement of sensor heads

- Cable lengths between 1 m and 30 m in 5 m increments

- Long service life

The Advantages

The sensors are available with a fixed cable for connection to an M18 amplifier or a detachable connection as well as different cable lengths. All components of the sensor set can be replaced individually. Mounting the sensor flush in metal minimizes the risk of damage. The integrated switching cycle and runtime counter provides additional information for predictive maintenance.

At a Glance

- Robust object detection at temperatures up to 250 °C (482 °F)

- Large operating distance of up to 50 mm

- Easy product selection: one amplifier is compatible with either sensor head and selectable cable lengths

- Automatic synchronization for interference-free operation of several sensor heads, even when connected in series

- IO-Link interface for parameterization, process and diagnostic data

- Plug-and-play: simple commissioning and replacement of the sensor head without re-parameterization