4/24/2025Reliable Object Detection—Regardless of Shape or Size

R305 Retroreflective Area Sensor with IO-Link

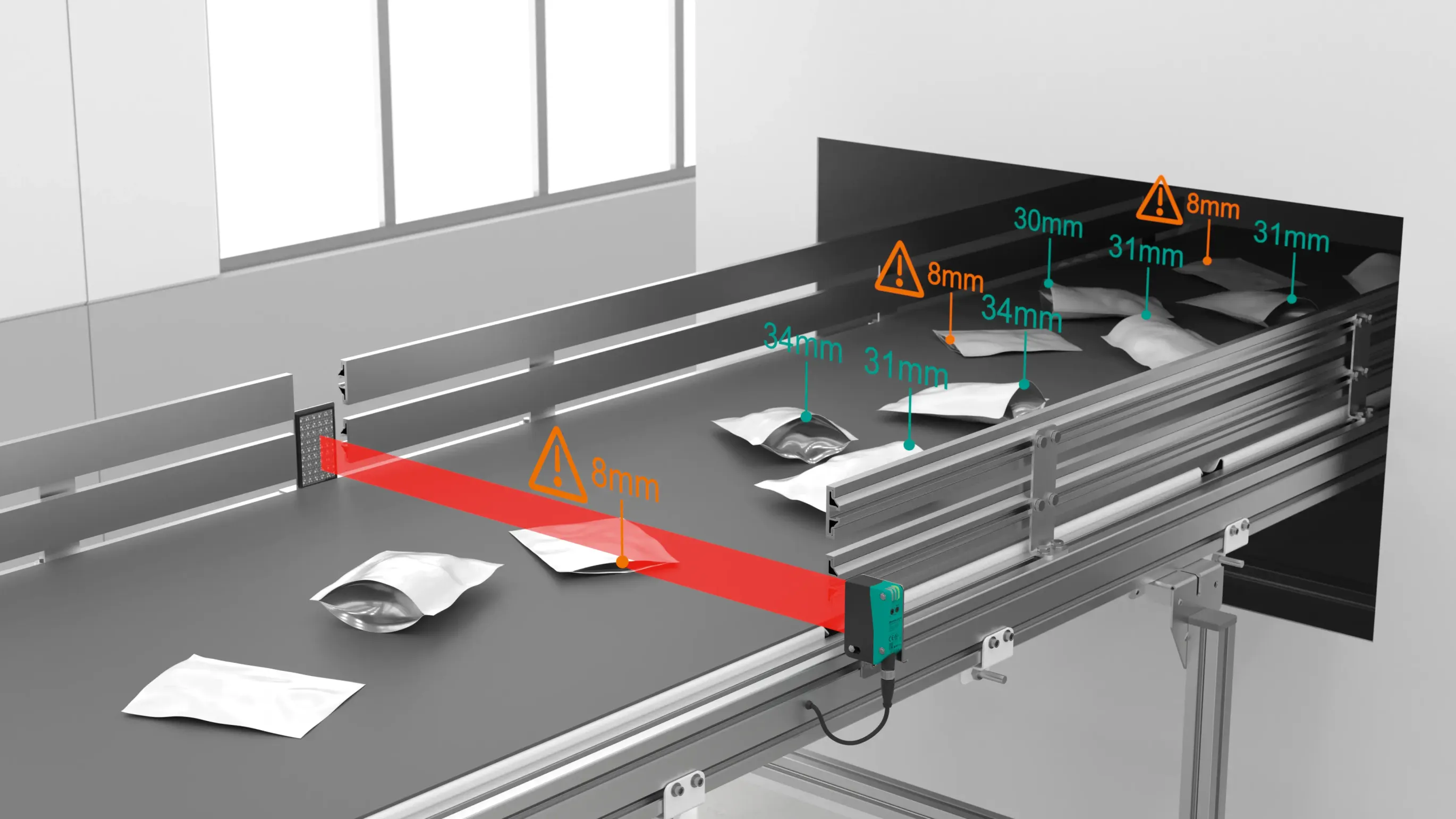

The R305 retroreflective area sensor from Pepperl+Fuchs reliably detects irregularly shaped objects from a height of just 2 mm. Due to individual settings, a light bandwidth of 60 mm, and a detection range of up to 4 m, it offers maximum flexibility for various applications. Discover the new retroreflective area sensor, which also features integrated height measurement and an IO-Link interface, providing significant advantages over conventional retroreflective sensors.

Reliable Object Detection Even for the Smallest or Non-homogeneous Objects

In numerous applications, precise and reliable object detection is essential for smooth operation. Traditional retroreflective sensors reach their limits, especially with very small or narrow objects that are not precisely aligned with the point-shaped detection area. At the same time, non-homogeneous objects with irregular contours can also trigger multiple switching operations. This is where the new R305 retroreflective area sensor comes in. With its wide light band instead of a point-shaped light beam, it can also detect very narrow object edges and only triggers a single object detection circuit for interrupted contours.

Maximum Flexibility for a Wide Range of Applications

With various setting options and its innovative light band consisting of five beams, each 12 mm wide, the R305 retroreflective area sensor offers maximum flexibility. Each of the beams can be switched off individually to block out interfering objects in the detection area or to align the total height of the light band to a narrow opening. The contrast level can also be adapted to the application in order to reliably detect objects made of clear glass, for example.

The photoelectric sensor offers a choice between two preset measuring modes: a long detection range up to 4 m (in standard resolution mode) or a high resolution up to 2 mm (in high resolution mode). Adaptations to the specific application are conveniently done via a rotary selector switch and a button directly on the sensor. The IO-Link interface provides even more flexibility, allowing to optimize and gradually change the range and resolution values.

IO-Link Interface for Optimized Processes and Predictive Maintenance

The predefined setting options offer a quick and efficient solution for various applications. Where the default settings reach their limits, IO-Link opens up additional and individual adjustment and optimization possibilities. The R305 retroreflective area sensor not only detects the presence of an object, but also measures its height in parallel. The additional measured values are transmitted to the control system via IO-Link. Their evaluation enables sorting, classification, or monitoring applications that contribute to quality improvement and process optimization. Moreover, the parallel transmission of measurement and status data via IO-Link creates the basis for predictive maintenance.

Easy Commissioning and Reduced Maintenance Effort

With the Easy Alignment Mode, the R305 retroreflective area sensor can be installed quickly and intuitively without time-consuming adjustment. A yellow LED indicates how the light band of the sensor should be aligned with the reflector. Using an adapter with an integrated deviation mirror, users can also simply mount the retroreflective sensor offset by 90 degrees. This space-saving side-looker version was specifically developed for tight spaces.

If the R305 retroreflective area sensor is switched off, for instance due to a maintenance-related system shutdwon, the sensor automatically adjusts to the new application environment via the Auto-Teach function when it is switched on again. Manual re-teaching is not necessary. During operation, the R305 automatically adjusts its light intensity using intelligent signal compensation, therefore neutralizing the effects of dust, dirt, or changing light conditions. This ensures consistently stable operation and keeps maintenance costs to a minimum.

At a Glance

- Reliable detection of the leading edge of an object, regardless of its shape and position

- Versatile: minimum detectable object (MDO) as small as 2 mm

- Application flexibility due to individual beam blanking and adaptable MDO

- Time-saving commissioning with predefined parameters and easy alignment mode

- Reduced maintenance enabled by auto-teach and intelligent signal compensation

- Integrated object height measurement enables sorting, classification, or monitoring applications