Collision Avoidance on Electrified Monorail Systems (EMS) in Automotive Production

Safe and Precise Distance Measurement with the R200 with Pulse Ranging Technology

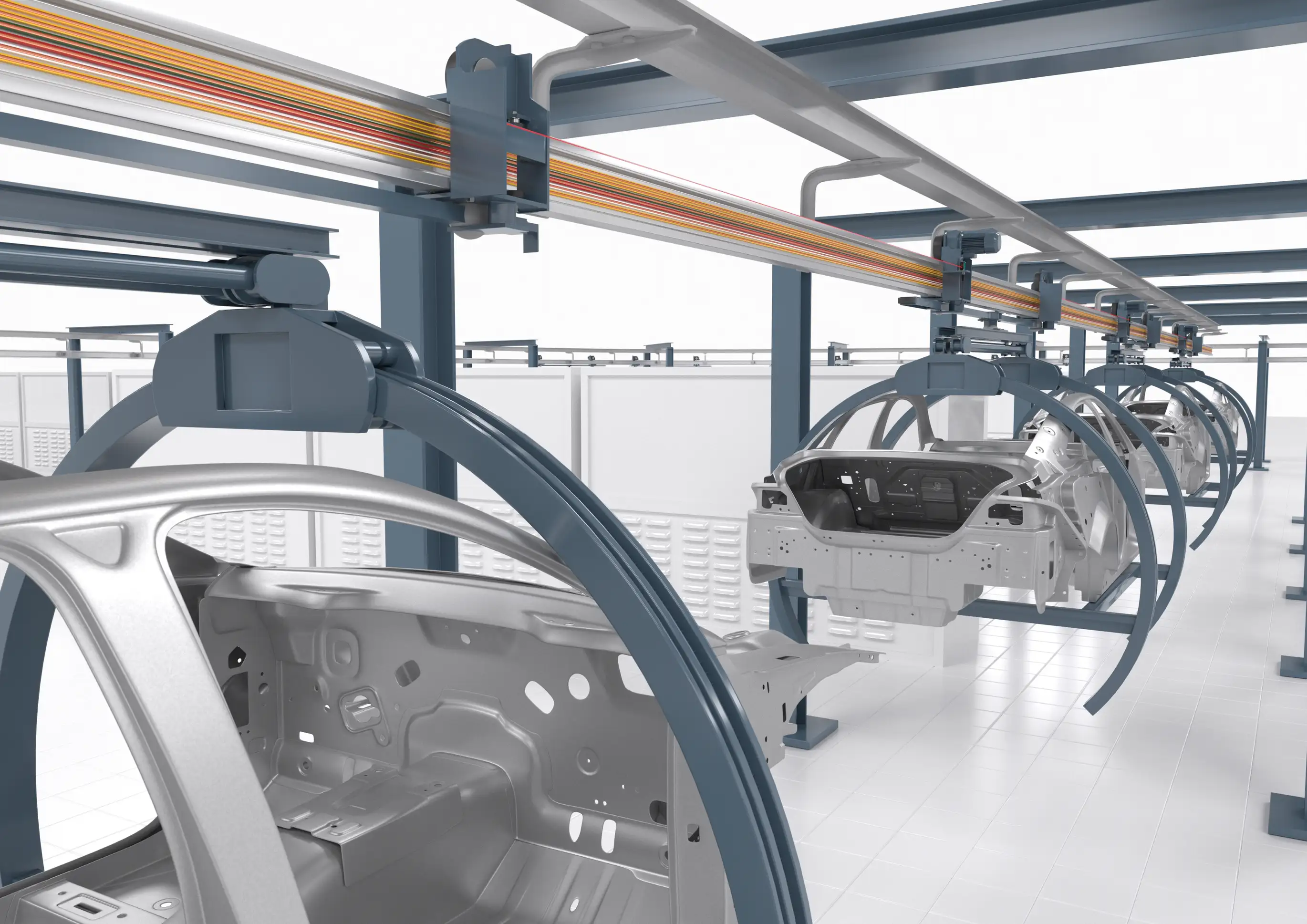

The Application

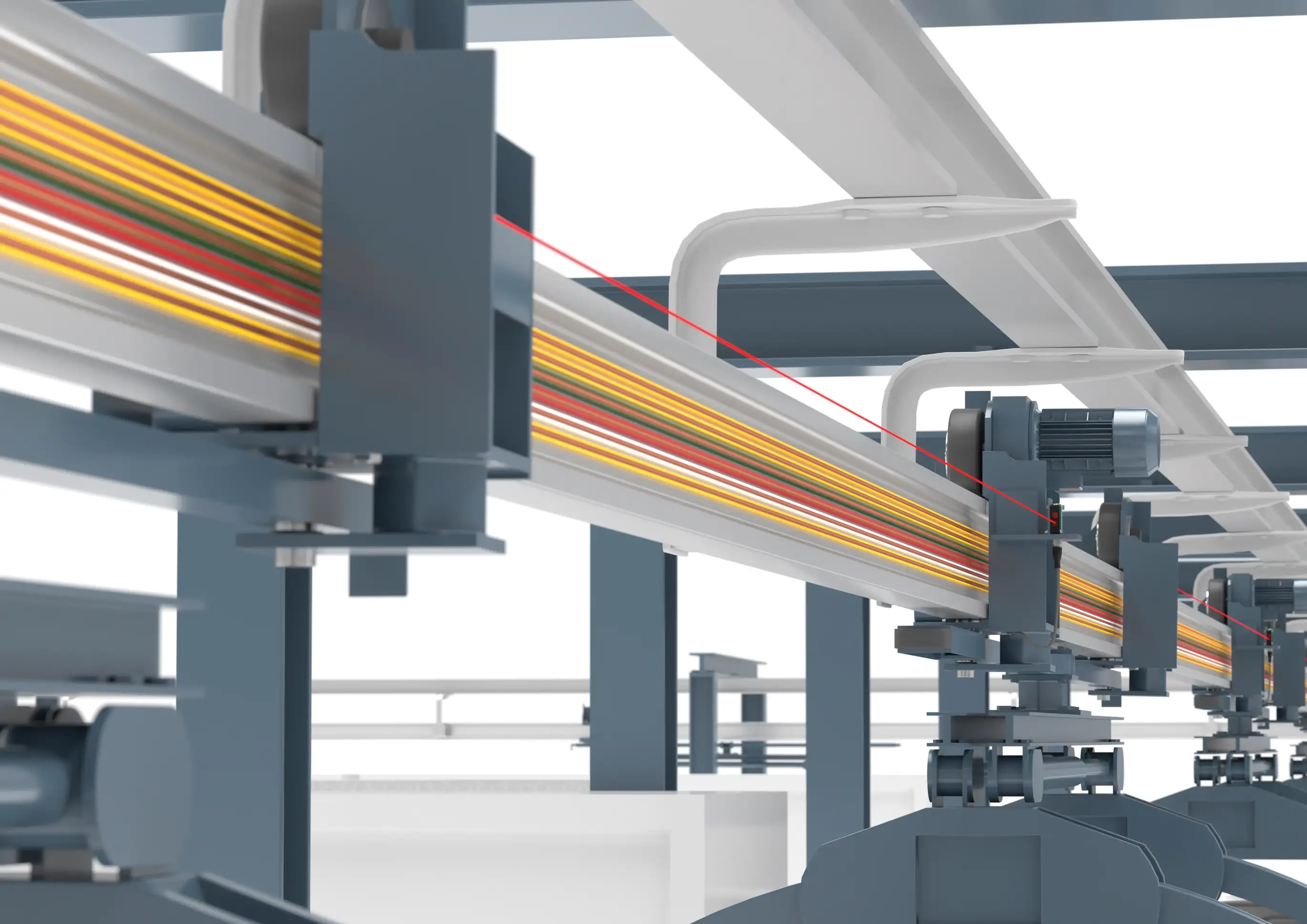

In automated vehicle assembly, electric monorail systems (EMS) are used to transport car bodies, components, or entire vehicles between assembly stations. These systems move

autonomously in complex route networks with many transfer points and intersections. To avoid collisions between several EMS vehicles, reliable distance measurement is essential—even with fast movements and changing environmental conditions such as dust, welding fumes, or reflective surfaces.

The Goal

A compact distance sensor that delivers precise measurement data at high speed—both at close range for distance control and over medium distances for predictive obstacle detection is needed. The sensor must be easy to integrate into existing control concepts and be IoT-capable. A robust design and high measurement stability, even with critical surfaces and under interfering light conditions, are essential.

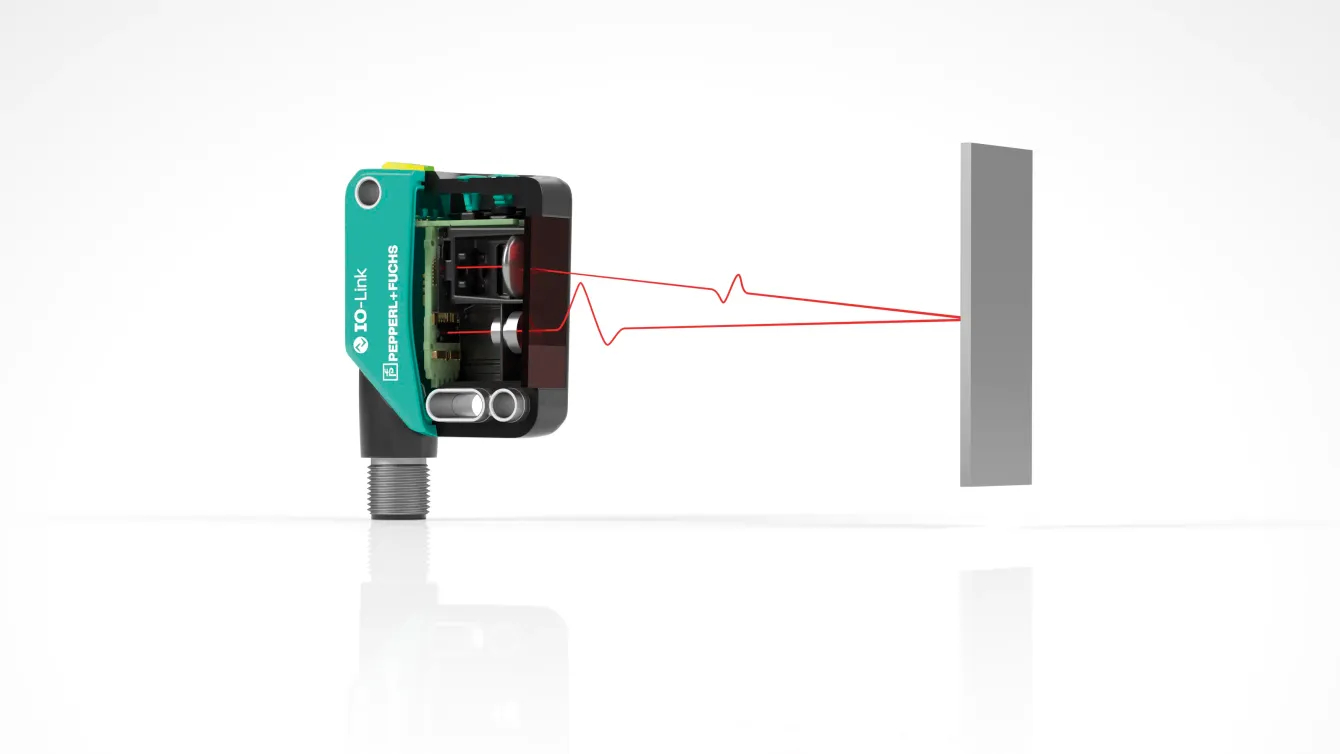

The Solution

The R200 distance sensor with Pulse Ranging Technology (PRT) from Pepperl+Fuchs offers the perfect combination of precision, range, and compact housing design. With over 250,000 laser pulses per second, the sensor measures with a repeat accuracy of ≤ 3 mm, including on moving electric monorail systems and with changing reflection properties. The range is up to 10 m, with reflector even up to 60 m—making it ideal for predictive collision avoidance. Installation is facilitated by the swivel connector design, which allows flexible positioning also in confined spaces.

Technical Features

- Pulse Ranging Technology

- Over 250,000 laser pulses per second

- Measurement at close range from 30 mm

- Range up to 10 m, with reflector up to 60 m

- Repeat accuracy up to ≤ 3 mm

- IO-Link interface

The Advantages

With its compact housing design of 15 × 41.7 × 50.6 mm, the R200 is ideal for installation on moving vehicle carriers, including where space is limited. Its high measuring frequency and repeat accuracy of ≤ 3 mm enable precise detection of fast-moving objects. The robust PRT measurement method delivers reliable measurement results despite interfering light or difficult surfaces. Due to the IO-Link interface with Smart Sensor Profile, the sensor can be seamlessly integrated into digital systems. In addition, the standardized operating concept of the R10x and R20x series simplifies the integration of different sensors within a system network.

At a Glance

- High-precision distance measurement up to 10 m, or up to 60 m with reflector

- Particularly compact design—for more flexibility where space is limited

- Intelligent Pulse Ranging Technology with a repeat accuracy of up to ≤ 3 mm

- Standardized IO-Link interface with Smart Sensor Profile for future-oriented automation

- Optimized, cost-effective design for a wide range of applications