Access Additional Parameters from Existing Field Devices

HART Loop Converter with Ex Approval for Increased Flow of Process Data

The Application

Gas burners for process heat can be operated with hydrogen (H2), which is produced as a by-product in other process steps. The quality of hydrogen can vary greatly, since depending on the production method, the gas has an irregularly high proportion of water vapor. The more moisture hydrogen contains, the lower the heating value of the gas and the efficiency of the burner. Fluctuating proportions of water vapor can impair the quality and continuity of the subsequent process.

The Goal

Regulating the hydrogen burner is intended to compensate for the irregularity of the fuel quality and to ensure uniform heat production. The heating value of the hydrogen should be determined efficiently and precisely to enable automatic adjustment of the flow of gas. If possible, this should be done without the use of additional components based on the existing field devices.

The Solution

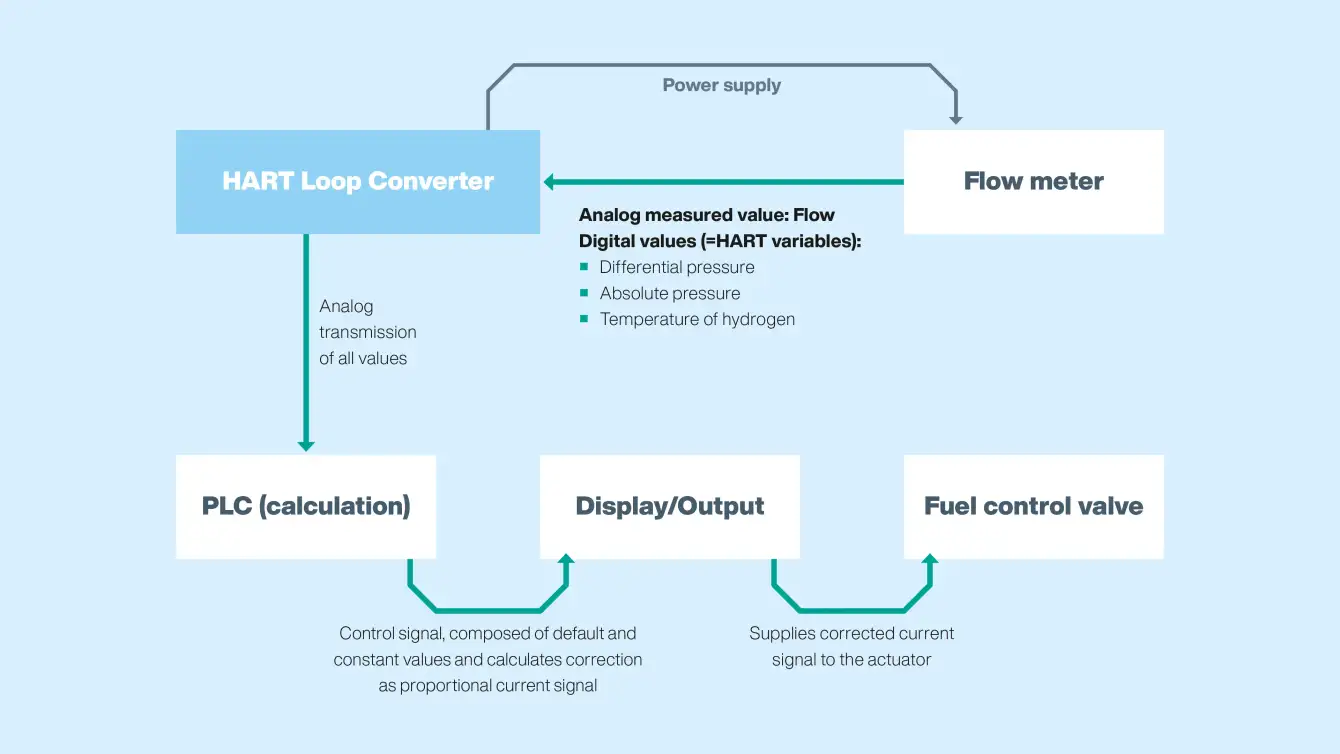

The HART loop converter (HLC) reads up to four variables of a HART-compatible field device and displays them as analog output signals. In bidirectional communication with the host system, relevant process parameters can be retrieved from the existing field devices without additional components. The converter records up to four digital HART signals, converts them into analog 4 … 20 mA power signals, and makes them available to the host system.

The HLC records additional control variables alongside the flow for the burner controller—in this application, these are the differential pressure in front of and behind the aperture, the absolute pressure, and the temperature of the hydrogen. As a HART analog input device, the HLC can provide power to a 2-wire transmitter and be connected in series between the field device and the controller, so that each transmitter is connected individually.

Technical Features

- 1-channel isolated barrier

- 24 V DC supply (Power Rail)

- HART field device input with transmitter power supply

- Signal splitter function

- 3 analog outputs 4 … 20 mA

- Output as sink or source

- Width 40 mm

- Can be configured via operating panel on the front

The Benefits

The point-to-point topology allows operation in burst mode: The field device delivers three to four updated measured values per second without actively querying. If the field device is not burst-compatible, the HLC switches to query mode. The HLC can output a digital value by splitting signals into three analog channels, making it available to different systems simultaneously. Trip amplification can be implemented via optional relays.

At a Glance

- The only HART loop converter on the market with approval for signals from hazardous areas

- For bidirectional communication between field device and host system

- Makes relevant process parameters available in the field without additional components

- Minimal hardware requirements, fast commissioning, use of existing 4 … 20 mA infrastructure

- Mechanically stable and space-saving design in the K-System, mounting on 35 mm DIN rail with supply via Power Rail

- Transfer of collective error messages to the controller